Apr 8, 2024

Our latest U.S. gas producer customer: Cows

Posted by TC Energy

Emphasizing the ‘natural’ in natural gas

Cattle are notorious for being big producers of methane. We can thank our insatiable appetites for beef and dairy and the resulting mass breeding of cattle, who themselves have even greater appetites for grass, legumes and silage.

Given the prominence of beef in our diets and cultures, humankind probably won’t curb its consumption anytime soon in a way that results in a major drop in methane emissions. However, there are some creative and productive solutions for mitigating the environmental impact of cattle.

One involves harnessing their prodigious digestive systems to turn out another source of energy—a source capable of supplying millions of cubic feet per day of natural gas to vehicles, homes, and businesses, not unlike a gas field trapped deep beneath the Earth’s surface.

That source: manure.

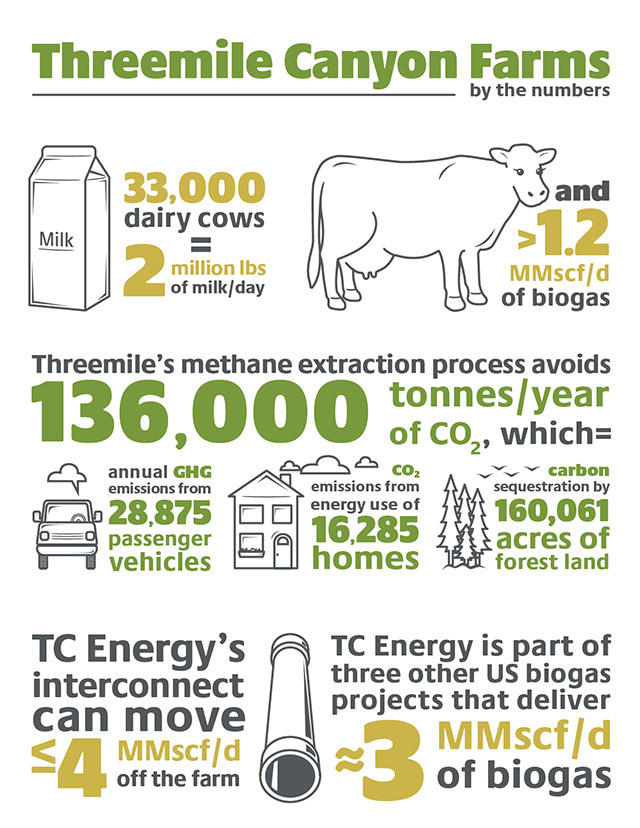

This is happening at a large scale at Threemile Canyon Farms in Oregon, where some 33,000 dairy cows produce 2 million lbs of milk each day. Those cows also currently produce 1.2–1.4 MMscf/d of renewable natural gas, or biogas, with room to grow. TC Energy owns the important role of making sure the gas reaches consumers in energy-hungry California via an interconnect brought in service last year.

Participation in the project is part of TC Energy’s commitment to helping remove emissions from the gas value chain while continuing to deliver affordable energy to consumers.

A broad, multitalented team was assembled to evaluate the Threemile biogas stream and develop a meter station equipped with proper analyzers, shut-in valving, and equipment to ensure the gas entering the pipeline is tariff quality. Now operational, flow meters on farm grounds deliver and receive gas at the same time.

Those flow meters sit near a processing facility that turns the manure into biogas. Threemile’s paradoxically messy-but-clean process involves mixing manure with water to form a sludge, which is then piped to a series of large in-ground pools—called digesters—that are tightly sealed with something of a “tent,” explained John Cordaway, the TC Energy U.S. business development manager who was involved with the project.

The biogas produced in the digesters is captured and piped through a system that removes all CO2 and harmful components such as sulfur and water, leaving high-quality methane. Once clean, the gas is compressed to a pressure that allows it to enter TC Energy’s Gas Transmission Northwest (GTN) system for delivery. Threemile’s overall process produces virtually no waste.

The interconnect can move up to 4 MMscf/d of biogas off the farm, a level that’s “definitely a goal the farm would like to attain” given the strong business case for the project, said JP Tan, who served as Threemile interconnect project manager. Government agencies are providing tax incentives for developers to build the infrastructure required to harvest biogas.

The benefits to the environment are also significant. As part of Threemile’s methane extraction process, some 136,000 tonnes/year of CO2 are avoided, equivalent to the annual greenhouse gas emissions from 28,875 passenger vehicles, CO2 emissions from the energy consumption of 16,285 homes, or carbon sequestration by 160,061 acres of forest land, according to stats provided by the farm.

And, when considering TC Energy’s involvement in other biogas projects in the U.S., the company is helping make an even larger impact. TC Energy is also receiving gas captured from cow manure at Town Hall Road in Wisconsin and, beyond the cow pastures, a landfill at Dane County in Wisconsin and hog manure at Ruckman Farm in Missouri, each of which delivers around 1 MMscf/d.

John notes that several other TC Energy pipelines have received inquiries from prospective developers and producers. Because of the high demand, the company is working to create a standard biogas meter skid that will cut installation cost and time, part of its effort to make future participation in these projects more seamless.